Choosing the right PCB assembly method is critical for the success and performance of your product. Two popular methods stand out: through hole PCB assembly services and surface mount technology (SMT). Each has its own advantages, and the choice depends largely on the requirements of your project.

In this post, we’ll explore the key differences between these two assembly techniques to help you decide which is the best fit for your project.

What Are Through Hole PCB Assembly Services?

Through hole PCB assembly involves inserting electronic components with leads into drilled holes on a printed circuit board (PCB). These leads are then soldered to pads on the opposite side of the board, ensuring a strong mechanical bond.

This method is often preferred for projects that demand high durability and reliability, particularly in environments with significant stress, vibration, or extreme temperatures.

Advantages of Through Hole PCB Assembly Services:

- Durability: The strong solder joint makes it ideal for applications in the aerospace and automotive industries, and industrial machinery.

- Ease of Prototyping: Components can be easily replaced or modified, which is particularly beneficial during the design and prototyping phase.

- High Power Capability: Through hole PCB assembly is better suited for components that need to handle high power, such as transformers and connectors.

Limitations of Through Hole PCB Assembly Services:

- Slower Production: The process is more time-consuming than surface mount technology, due to the drilling and manual placement and soldering required.

- Larger PCB Space Requirement: The components and drilled holes require more space, leading to larger printed circuit boards.

What Is Surface Mount Technology (SMT)?

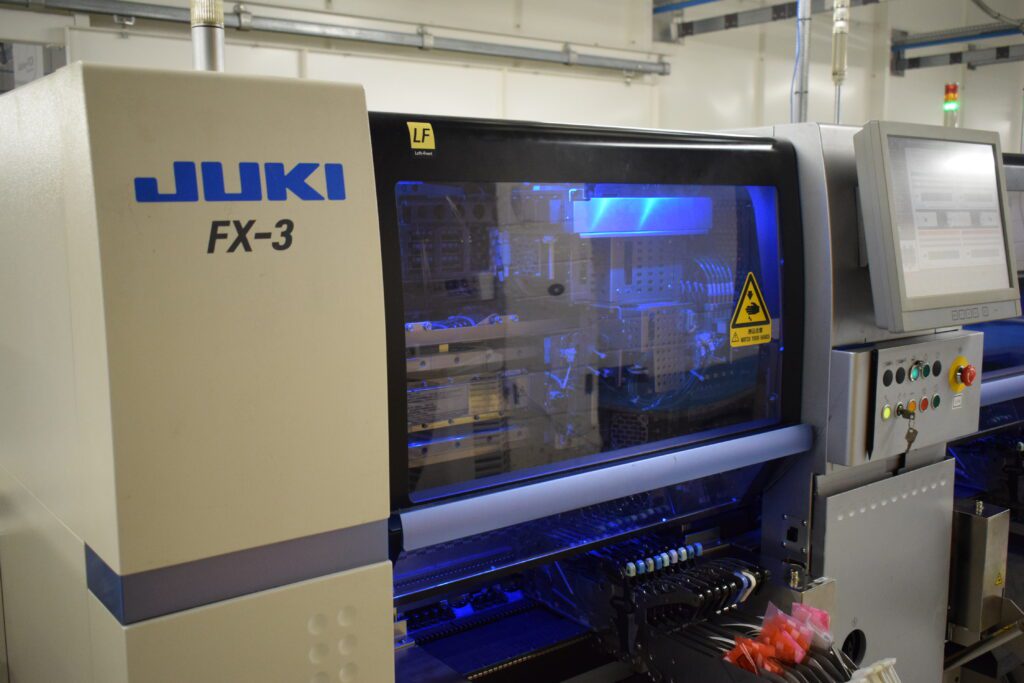

Surface mount technology involves mounting components directly onto the surface of the PCB. Unlike through hole assembly, SMT does not require drilling, and components are much smaller.

This method has become the industry standard for high-volume manufacturing due to its speed and efficiency.

Advantages of Surface Mount Technology:

- Compact Designs: SMT components are smaller, allowing for denser and more compact PCBs.

- Automation: SMT is highly compatible with automated assembly and testing, enabling faster production at scale and fewer undetected errors.

- Cost-Effectiveness: The elimination of drilled holes and manual soldering reduces manufacturing costs.

- High-Frequency Performance: SMT components are better suited for high-frequency applications due to reduced parasitic inductance.

Limitations of SMT:

- Mechanical Strength: SMT components may not be as mechanically robust as through hole components.

- Limited Power Handling: SMT is not ideal for components requiring high power or exposure to harsh conditions.

- Prototyping Challenges: Difficult to modify or replace components during prototyping.

Comparing Through Hole and SMT: The main differences

| Feature | Through Hole PCB Assembly Services | Surface Mount Technology |

|---|---|---|

| Durability | Excellent for high-stress environments | Moderate |

| Component Size | Larger components | Smaller, compact components |

| Production Speed | Slower due to manual processes | Faster due to automation |

| Cost | Higher due to labor and materials | Lower per unit at scale |

| Applications | Aerospace, automotive, industrial | Consumer electronics, high-frequency devices |

Which Method Is Right for Your PCB Assembly?

The choice between through hole PCB assembly services and surface mount technology depends on your project’s specific requirements. Here’s a quick guide:

- Choose Through Hole PCB Assembly Services if:

- Your project requires extremely high durability and reliability.

- The final product will be required to operate in harsh environments.

- You’re working with components that require high power.

- Choose SMT if:

- You need compact, lightweight designs.

- Your project involves high-volume production.

- Cost and speed are the most critical factors.

Hybrid Approach: The Best of Both Worlds in PCB Assembly

In some cases, a hybrid approach may be the ideal solution.

By combining through hole and SMT components, you can leverage the benefits of both techniques. For example, through hole components can be used for power handling and connectors, while SMT can be used for compact, high-density circuits.

If you’re unsure which method to choose, call Active-PCB Solutions. Our expertise can guide you in selecting the best approach for your specific needs.

Would you like to learn more about how through hole PCB assembly services can enhance your product’s performance? Contact us today to get started!