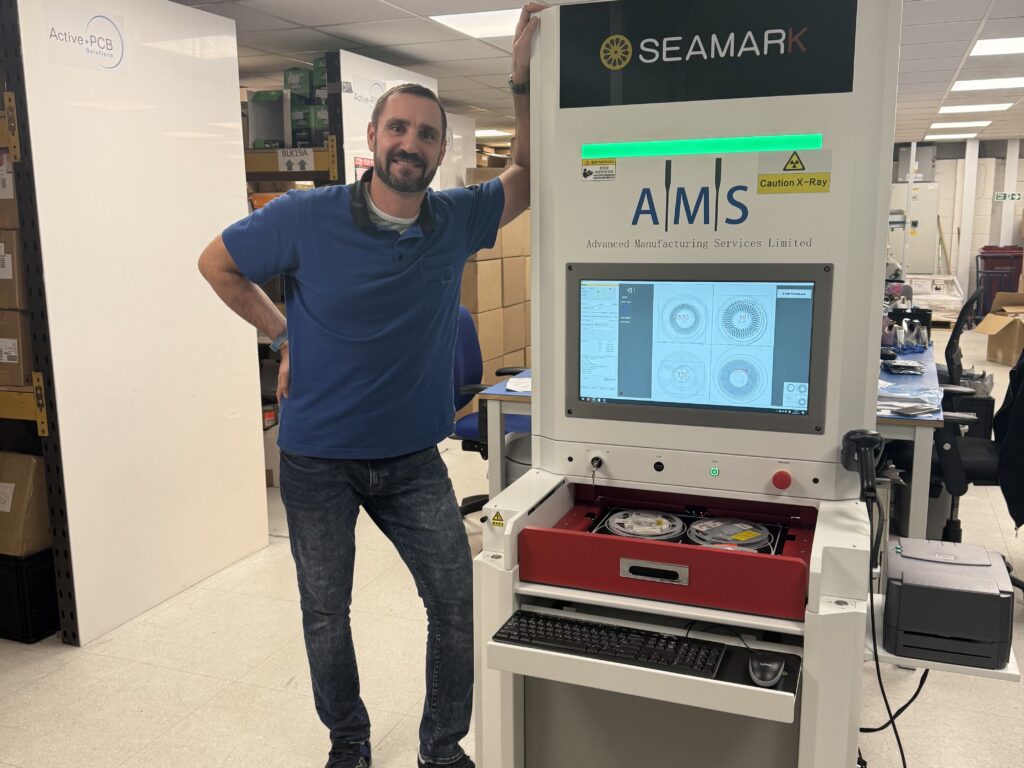

At Active-PCB Solutions, we know that accuracy, efficiency, and seamless integration are not optional, they’re an essential part of our manufacturing process. That’s why we’re excited to introduce our new Seamark XC1000 X-Ray Component Counter which has just been installed on our shop floor by Advanced Manufacturing Solutions Ltd. The next-generation offline X-ray component counting system is designed to redefine how we manage and verify our SMD component inventory.

You can find out more about this new technology and how we intend to put it to full use below!

Precision Counting Powered by AI

Leveraging an advanced AI algorithm, this intelligent Seamark XC1000 X-Ray Component Counter system provides 99.99% counting accuracy for all SMD components sized 01005 and above, meaning we can say goodbye to manual errors and time-consuming reel unpacking.

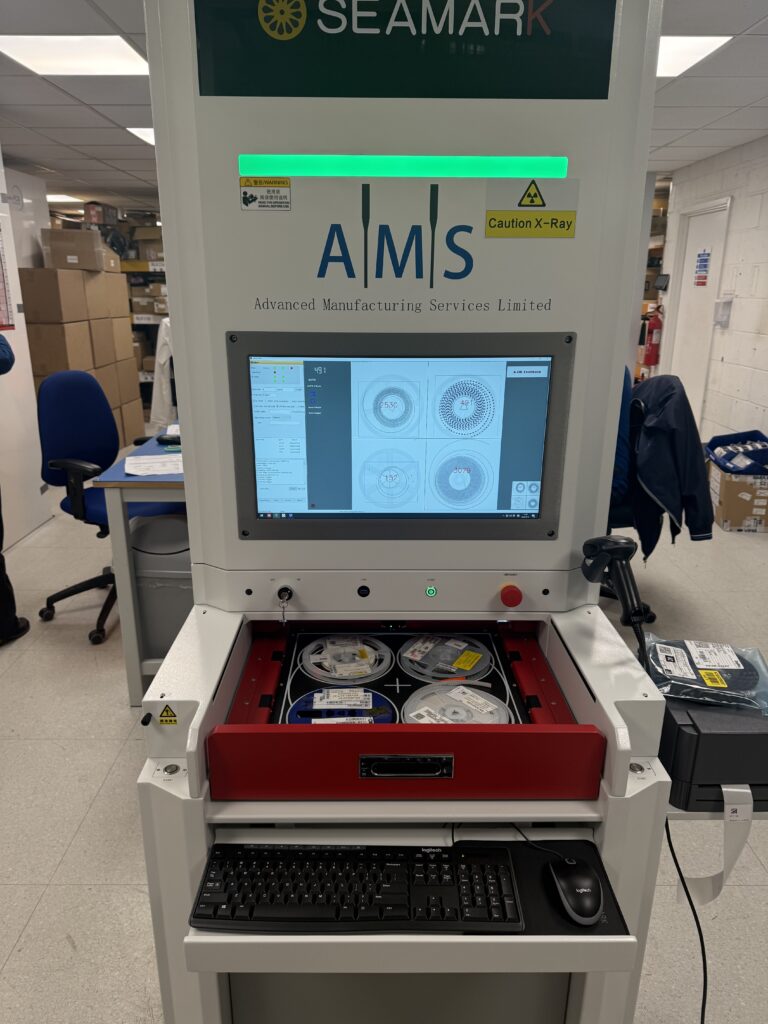

The XC1000 counts 1 to 4 reels simultaneously with no unspooling, no guesswork, and no downtime.

Ergonomic Design Meets Automation

The XC1000 features an ergonomically designed workstation where the operator can sit comfortably and monitor the easy-to-read counter screen. With an automated stage movement system and anti-pinch safety design, reel handling is simple, safe, and efficient.

The unit is compact and mobile, thanks to built-in wheels for easy relocation.

Smart Labeling and Real-Time Integration

Mislabeling and manual input errors are inevtiable and costly. However with its error-proof labeling function, the XC1000 automatically detects and recognises each reel, instantly printing the correct label via a TSC industrial printer. This intelligent workflow is further enhanced by seamless real-time integration with MES, ERP, and WMS systems, enabling live data exchange and automatic result uploads.

Built for the Modern SMT World

The XC1000 is built to handle the full range of reel sizes (7”–15”), heights (5–80mm), and component types including moisture-proof bag packaging, bulk materials, and JEDEC trays. Its amorphous silicon flat panel detector delivers sharp, high-resolution images with a 430mm × 430mm field of view, supported by four optional cameras for automatic barcode reading.

Industry-Leading Database & Cloud Intelligence

What sets the Seamark XC1000 X-Ray Component Counter apart is its dynamic, global X-ray component database, which includes:

- 15,000+ material profiles

- 60 million+ testing images

- 700,000+ core reference images

- Weekly updates with 160,000 new images

- Over 8.6 million classification training images

This continually evolving database ensures compatibility with 99.2% of global components. Updates are cloud-synced monthly, keeping the whole system current and reliable.

Key Technical Specs at a Glance

- Input Power: 220V, 10A, 50–60Hz

- Control System: Windows 10 64-bit

- X-Ray Source: Sealed microfocus (30–80KV, up to 1000 μA)

- Detector: 3072×3072 matrix, 139μm resolution

- Max Output Power: 56W

- Counting Speed: Fully automated, operator training not required

Future-Proofing Our Inventory Management

The Seamark XC1000 X-Ray Component Counter is the latest in a series of investments by Active-PCB into our shop floor equipment. We believe that by investing in the latest technology, alongside investing in our people, we can position ourselves as one of the country’s top CEMs.

If you’re an OEM and you’d like a tour of our facilities, contact us to book a visit.