For UK printed circuit board manufacturers including Active-PCB Solutions, functional testing plays an indispensable role in ensuring the performance and reliability of the electronics we manufacture. Functional testing helps us to maintain high standards of performance, reduce costs, and build trust with clients and their customers.

what is functional testing for UK printed circuit board manufacturers?

Functional testing is a quality assurance process that verifies whether a PCB operates as intended in its final application. Unlike basic electrical tests that check for issues such as open circuits or short circuits, functional testing evaluates the board’s performance under simulated operating conditions. This involves applying real-world inputs and measuring the outputs to confirm that the PCB behaves as expected within a given system.

Let’s take a deeper look at why it’s crucial for UK printed circuit board manufacturers to invest in the staff and technology to fulfil this function.

Why is functional Testing important?

- Ensuring Vital Reliability: Functional testing identifies defects or malfunctions that could compromise the PCB’s operation. By addressing these issues before the product reaches the customer, manufacturers reduce the risk of failure, so they won’t end up with dissatisfied customers and complaints. Untested, unreliable PCBs could seriously harm the reputation of a company and depending on the nature and implications of the failure, could end up being a very costly mistake.

- Meeting UK Industry Standards: Functional testing helps manufacturers comply with stringent industry regulations and certifications. For UK electronics manufacturers like Active-PCB Solutions, adherence to these standards is a cornerstone of our reputation for quality and precision.

- Reducing A Product’s Time-to-Market: Catching and resolving errors which occur during the manufacturing phase saves valuable time in the product development lifecycle. This is particularly crucial for industries like automotive, aerospace, and the manufacture of medical devices, where delays can have significant financial and reputational impacts.

- Maximising Cost Efficiency: Detecting faults as early as possible in the production process reduces the costs associated with rework, warranty claims, and recalls – not to mention reputational hits. Functional testing provides a proactive approach to minimising such expenses.

How UK PCB Manufacturers Implement Functional Testing

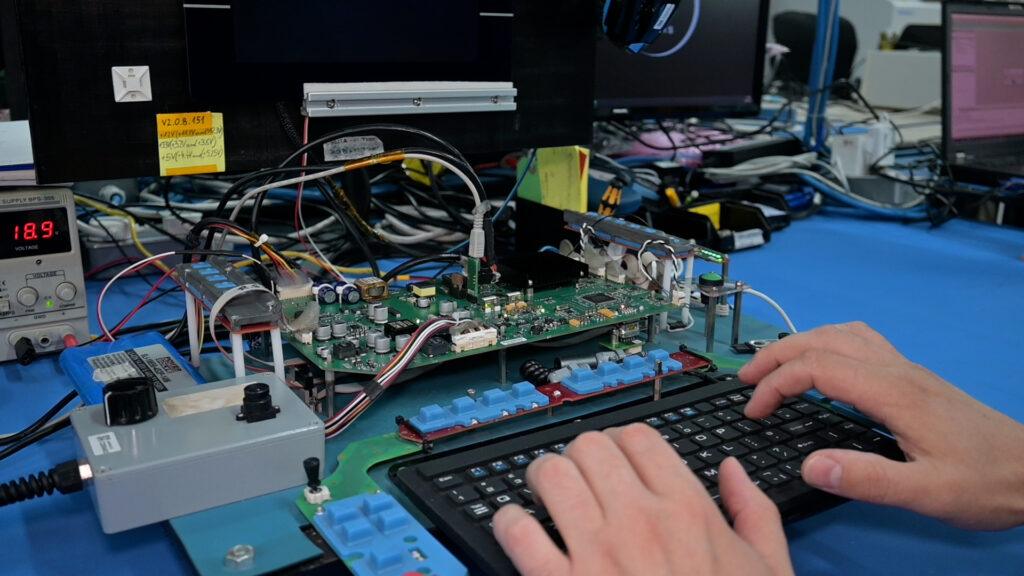

UK printed circuit board manufacturers use state-of-the-art technologies and methodologies to perform comprehensive functional tests. Here’s how companies like Active-PCB Solutions ensure that our PCBs meet rigorous performance criteria:

- Collaboration with Clients: At Active-PCB Solutions, we work very closely with our clients to understand the unique requirements of their applications. We then develop bespoke test fixtures tailored to the specific design and application of each PCB, which simulate the operational environment. This allows for accurate testing of the board’s functions.

- Automated Testing Systems: Automation enhances the precision and efficiency of functional testing. Advanced test systems can execute multiple test cases in quick succession, ensuring thorough coverage and consistent results.

- Comprehensive Data Analysis: Functional testing generates valuable data that manufacturers analyse to identify trends and improve processes. By continuously refining their testing methodologies, UK manufacturers stay ahead of industry demands.

Functional Testing at Active-PCB Solutions: A Commitment to Excellence

At Active-PCB Solutions, functional testing is more than a quality control step; it is a fundamental aspect of our manufacturing philosophy.

We have a dedicated team of engineers and cutting-edge testing facilities to deliver PCBs that meet and exceed our client’s expectations. By prioritising functional testing, we can reinforce our reputation as a trusted partner among UK printed circuit board manufacturers.