When it comes to bringing your electronic projects to life, choosing the right contract electronics manufacturer (or CEM) is critical. Whether you’re developing cutting-edge medical devices, consumer electronics, or industrial equipment, the quality, reliability, and support offered by your manufacturing partner can make or break your product.

Here’s a guide to help you identify what to look for when selecting the perfect manufacturer for your needs.

1. Proven Expertise and Experience

Start by evaluating the track record of potential manufacturers. A reputable contract electronics manufacturer should have a history of delivering high-quality products across various industries. Look for case studies, testimonials, or a portfolio of past projects to gauge their expertise in producing reliable and high-performance solutions. Active-PCB have been a leading presence in the market since 1997 so you can be assured of our expertise.

2. Advanced Manufacturing Capabilities

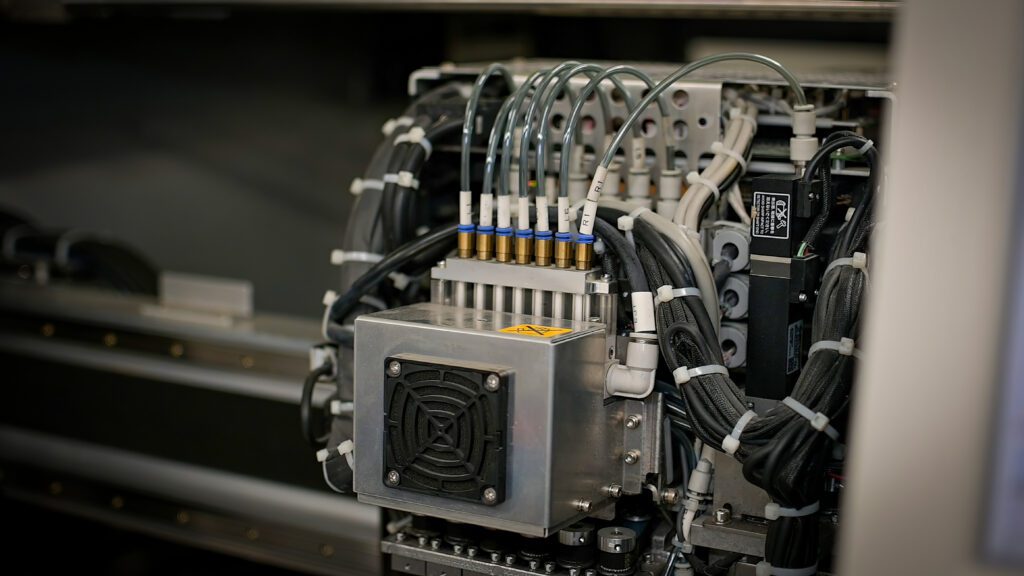

The capabilities of a contract electronics manufacturer can significantly influence the quality and scalability of your product. Look for features such as:

- Modern Equipment: Ensure the manufacturer regularly invests in new, state-of-the-art machinery for precision and efficiency.

- PCB Layer Capabilities: If your project requires multilayer PCBs, confirm they can handle the complexity.

- Material Choices: Verify their ability to source high-quality materials suited for your application.

- Assembly Services: For complete products, check if they offer both PCB fabrication and assembly under one roof, ensuring a streamlined process. Active PCB offer Box Build assembly capabilities making the production process smoother for clients.

3. Quality Assurance and Certifications

Quality assurance is paramount in electronics manufacturing. Seek a CEM partner that adheres to industry standards and holds certifications such as:

- ISO 9001: For quality management.

- IPC-A-610: For assembly standards.

- RoHS Compliance: To ensure environmentally friendly manufacturing.

You can see a list of our extensive qualifications and certifications here.

Ask about their testing processes, such as Automated Optical Inspection (AOI), X-Ray inspection and functional testing, which ensure every product meets rigorous quality standards.

4. Customisation and Design Support

Every project is unique, so a good manufacturer should offer design flexibility and customisation options. Many leading electronics manufacturers provide design-for-manufacturability (DFM) services, helping you refine your designs to reduce costs and avoid production errors. This is particularly valuable for startups or companies new to the electronics industry.

5. Scalability and Lead Times

Your chosen CEM should have the capacity to grow with your business. Consider whether they can scale production quickly and meet tight deadlines without compromising on the quality. Ask about their lead times for prototyping and mass production to ensure they align with your project timelines.

At Active-PCB, we are able to take your electronics from prototype right through to mass production seamlessly, utilising our off-shore partners.

6. Transparency and Communication

Clear communication is a hallmark of a reliable partner. Choose a CEM that is upfront about pricing, lead times, and potential challenges. A dedicated account manager or support team can make the process smoother, especially for complex projects.

7. Competitive Pricing

While cost shouldn’t be the sole determining factor, it is still crucial. Compare quotes from several electronics manufacturers to ensure you’re getting competitive pricing for the services offered. Be wary of unusually low prices, as they may indicate compromises in quality or reliability.

8. Supply Chain Management

An electronics manufacturer’s ability to source quality components and materials on time can directly impact your product’s success. Look for a company with a robust supply chain, access to a global network of suppliers, and an emphasis on minimising lead times and costs.

9. Geographic Location

While many manufacturers operate internationally, consider the benefits of proximity and consider UK-based services. Local electronics manufacturers may offer quicker shipping and easier communication, while overseas partners might provide cost savings. Evaluate which option suits your project’s needs better.

10. Post-Production Support

Finally, a great contract electronics manufacturer will offer post-production services such as troubleshooting, repairs, and lifecycle management. These services can save you time and resources in the long run, ensuring your products perform optimally in the field.

At Active-PCB, we pride ourselves on delivering exceptional manufacturing solutions tailored to your specifications. Whether you need precision PCB fabrication or end-to-end electronics manufacturing services, we’re here to help your projects thrive. Contact us today to discuss your requirements!