What Is An SMT Machine And How Does It Work?

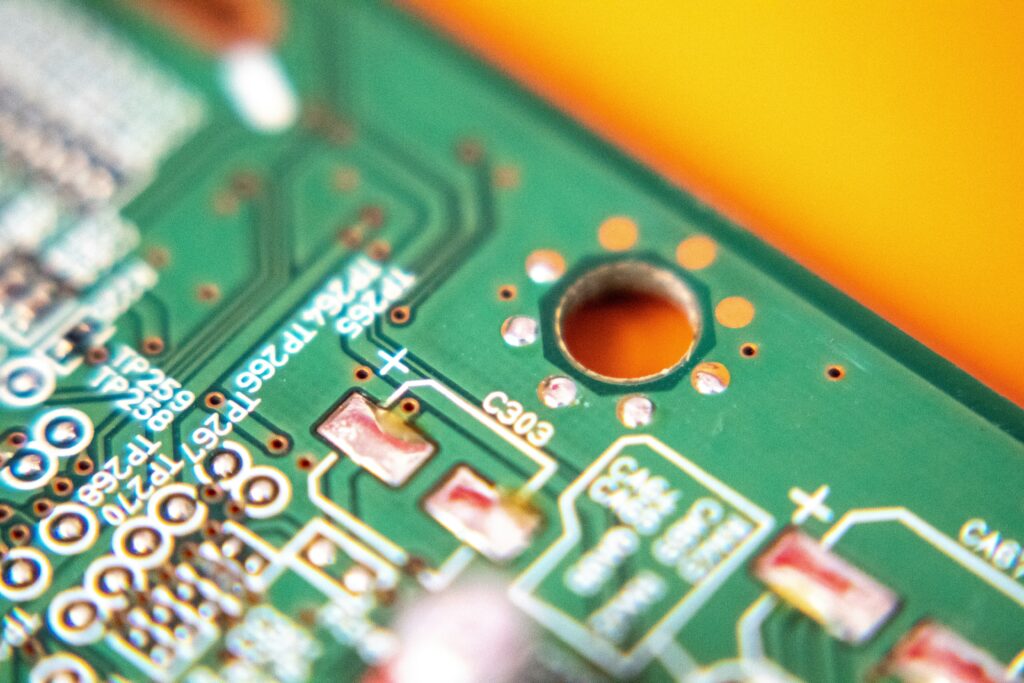

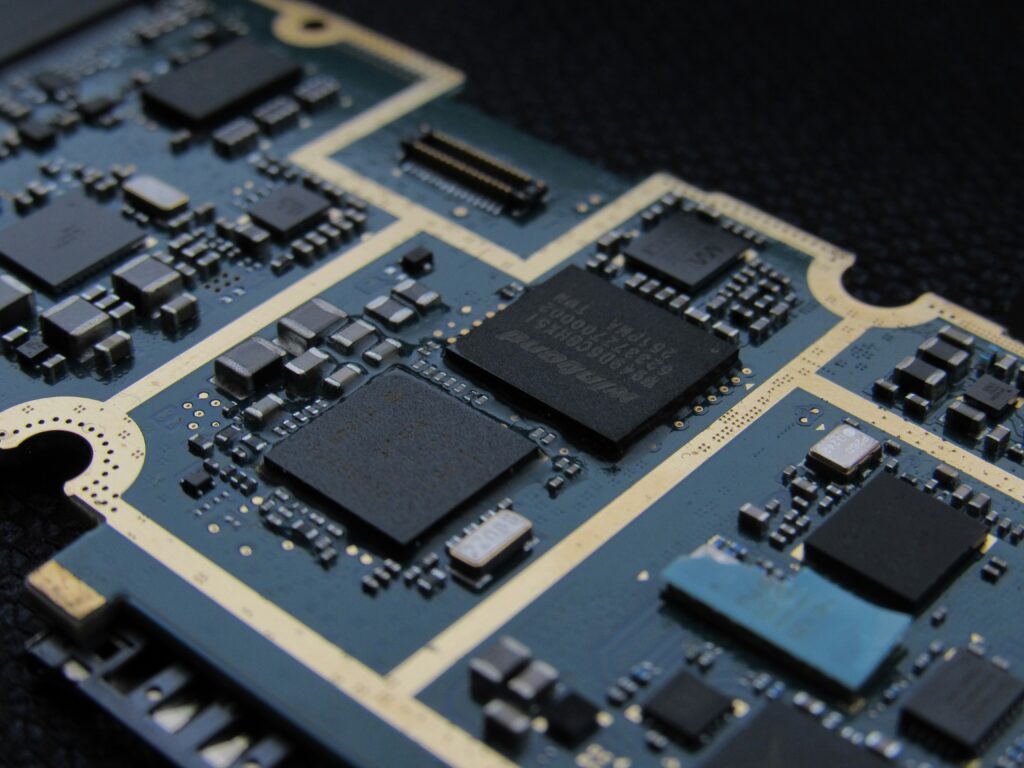

Surface Mount Technology (SMT) has been responsible for changing the electronics manufacturing industry in a huge way. Automation allows for faster, more efficient, and more compact circuit board assembly. At the heart of this process lies the SMT machine, a sophisticated piece of equipment designed to precisely place electronic components onto printed circuit boards (PCBs). […]

What Is An SMT Machine And How Does It Work? Read More »