As demand for electronics increases, manufacturers like Active-PCB Solutions are facing the the challenge of delivering high-quality printed circuit boards (PCBs) faster than ever before. This is where automation steps in as a game-changer, especially for quick turn PCB assembly services. In this article, we’ll take a look at how automation and advanced manufacturing techniques are transforming the PCB assembly process, enhancing both the speed and accuracy of production.

The Need for Speed: Why Quick Turn PCB Assembly Matters

Quick turn PCB assembly refers to the expedited production of printed circuit boards which allows businesses to move from prototype to production rapidly. This approach is invaluable for companies looking to gain a competitive edge, minimise their products’ time-to-market, and respond quickly to testing and customer feedback. However, achieving these goals demands more than just a streamlined workflow; it requires a high level of precision and efficiency that only automation can provide.

Key Automation Technologies Revolutionising PCB Assembly

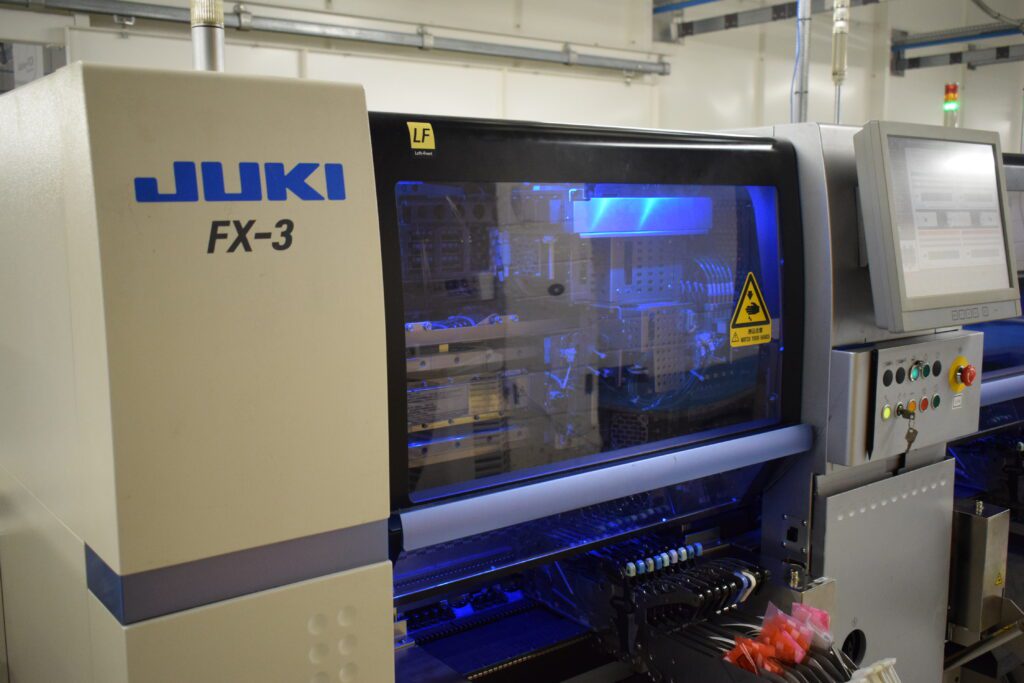

a. Surface Mount Technology (SMT) Automation

SMT automation is at the heart of modern PCB assembly. Our Juki Pick-and-Place machines can position thousands of components per hour with exceptional accuracy. These machines use advanced vision systems to ensure precise alignment and placement, drastically reducing manual errors and with far quicker production times.

b. Automated Optical Inspection (AOI)

Quality control is a significant bottleneck in manual assembly processes. Automated Optical Inspection systems use cameras and machine learning algorithms to detect soldering defects, misalignments, and other issues in real-time. AOI ensures that only flawless PCBs move forward in the production line, maintaining quality without slowing down operations.

c. Robotic Soldering

Automated soldering robots offer consistent quality by maintaining precise temperature control and solder volume. This consistency is vital for complex boards with high component density, where manual soldering could lead to errors and rework, delaying the process.

d. Automated Testing and Diagnostics

Functional testing is a critical step in ensuring that PCBs perform as intended. Automated test equipment (ATE) can execute comprehensive diagnostics faster than manual testing, identifying faults early in the process and preventing defective boards from reaching customers.

Benefits of Automation in Quick Turn PCB Assembly

a. Enhanced Speed and Efficiency

By minimising manual intervention, automation significantly reduces assembly times. Tasks that once took hours can now be completed in minutes, making it possible to meet tight deadlines without compromising on quality.

b. Improved Accuracy and Consistency

Automation eliminates human errors, ensuring consistent placement and soldering of components. This accuracy is particularly beneficial for high-frequency PCBs and applications where even minor defects can cause significant performance issues in important sectors such as medical and defence.

c. Cost Reduction in the Long Run

While the initial investment in automation equipment can be high, the reduction in labour costs, fewer defects, and faster turnaround times contribute to significant cost savings over time.

Challenges and Considerations

Despite its advantages, adopting automation in PCB assembly comes with challenges. High upfront costs, maintenance of automated systems, and the need for skilled operators and programmers can be barriers for some manufacturers.

However, as technology advances and costs decrease, automation is becoming more accessible, even for small to medium-sized enterprises.

The Future of Quick Turn PCB Assembly: Full Automation?

Looking forward, the integration of AI and machine learning with automation holds exciting possibilities. Predictive analytics could foresee potential failures before they occur, while machine learning algorithms could further refine accuracy and efficiency. Fully automated, smart factories could soon become the standard, enabling even faster and more reliable quick turn PCB assembly services.

Automation is no longer a luxury but a necessity for manufacturers aiming to stay competitive in the PCB assembly industry. By enhancing speed, accuracy, and efficiency, automated systems are paving the way for a future where quick turn PCB assembly becomes even quicker and more reliable. As technology continues to evolve, embracing automation will be key to unlocking new levels of productivity and innovation.

Looking to accelerate your PCB assembly process?

Contact us to learn more about our automated quick turn PCB assembly services and how we can help you bring your products to market faster!

Follow the Active-PCB LinkedIn page for updates!