Consumer demand for electronic devices continues to rise at an exponential rate. However, this surge in electronic consumption has led to a growing environmental concern: electronic waste (e-waste). Printed circuit boards (PCBs) are a significant component of electronic devices, and their disposal contributes to this global challenge. Fortunately, PCB rework and refurbishment offer sustainable alternatives that can reduce environmental impact while saving costs and resources.

Reducing Electronic Waste with PCB Rework

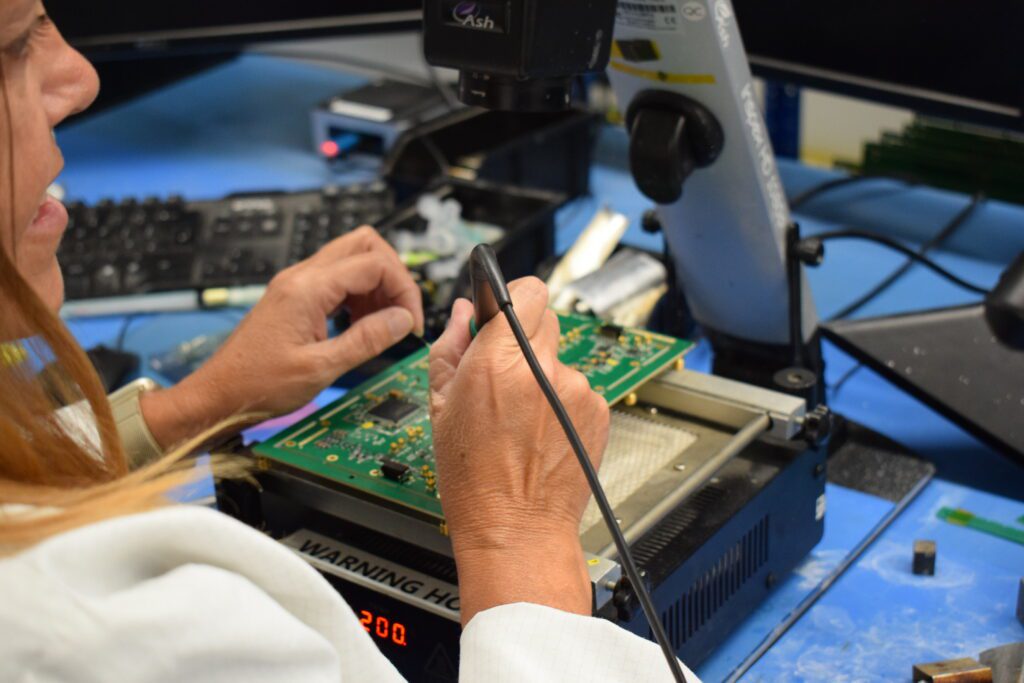

One of the most pressing environmental benefits of PCB rework and refurbishment is the reduction of e-waste. Instead of discarding faulty or outdated PCBs, reworking and refurbishing them extends their lifespan.

This practice prevents obsolete boards from ending up in landfill, where they would contribute to hazardous waste problems due to any toxic materials they may contain, such as lead, mercury, and brominated flame retardants.

Conservation of Raw Materials

PCBs are made from a combination of metals, plastics, and other materials, many of which require significant energy and resources to extract and manufacture.

By refurbishing existing PCBs, the demand for new raw materials is reduced. This conservation of resources decreases the need for mining and extraction, which often lead to deforestation, soil degradation, and water pollution.

Energy Efficiency and Carbon Footprint Reduction

Manufacturing new PCBs is an energy-intensive process that generates a substantial carbon footprint. The mining, refining, and processing of raw materials, along with the fabrication and assembly of new circuit boards, require large amounts of electricity and water.

In contrast, reworking and refurbishing existing PCBs require far less energy, making them an environmentally responsible choice that helps lower carbon emissions associated with electronic production.

Minimising Hazardous Waste

PCBs often contain hazardous substances, including heavy metals and chemical coatings, which can be harmful to both human health and the environment if improperly disposed of. By reworking and refurbishing old and obsolete PCBs, these hazardous materials are kept out of landfills and prevented from contaminating soil and water sources. This not only helps protect ecosystems but also ensures compliance with environmental regulations and sustainability initiatives.

Supporting a Circular Economy

The concept of a circular economy emphasises reducing waste, reusing materials, and recycling products to create a sustainable system. PCB rework and refurbishment align with this model by extending the functional life of electronic components rather than discarding them after a single-use cycle. By promoting repair and reuse, businesses and consumers alike contribute to a more sustainable approach to electronics manufacturing and consumption.

Cost Savings and Economic Benefits

In addition to its environmental advantages, PCB refurbishment can also be financially beneficial. Repairing and upgrading existing printed circuit boards is often more cost-effective than manufacturing new ones, making it an attractive option for businesses looking to reduce expenses while maintaining high-quality performance in their electronic devices.

PCB rework and refurbishment present a viable and eco-friendly solution to the growing problem of e-waste. By extending the lifespan of circuit boards, reducing raw material consumption, lowering energy usage, and minimising hazardous waste, this practice plays a crucial role in protecting the environment.

As industries and consumers continue to prioritise sustainability, adopting PCB rework and refurbishment strategies can make a meaningful difference in reducing electronic waste and promoting a greener future.

If you’re interested in reworking and refurbishing old PCBs, get in contact with us to find out how we can help.