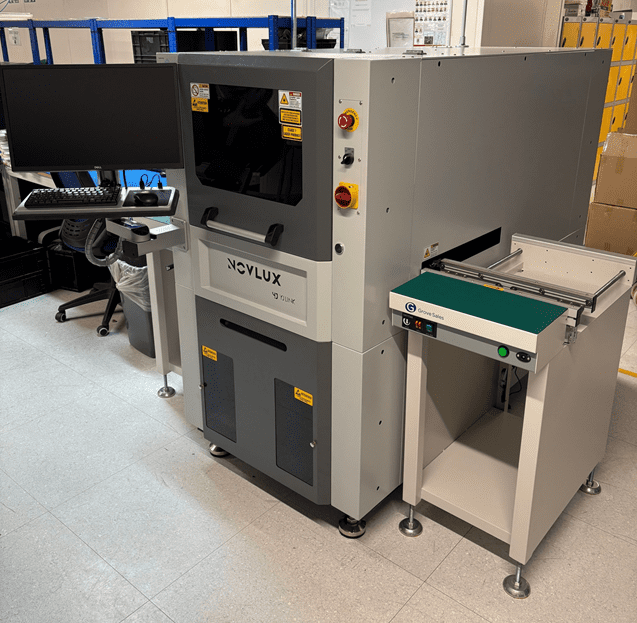

We’re excited to announce the successful installation of our new YJ Link NOVLUX Laser Marker! This cutting-edge technology, supplied to us by Altus Group, marks an exciting milestone in improving our operations, with an aim of enhancing traceability and repeatability within our manufacturing process.

What is the YJ Link NOVLUX Laser Marker?

The YJ Link NOVLUX Laser Marker is a state-of-the-art system that uses laser technology to etch precise markings onto various materials, including printed circuit boards. Unlike traditional methods, which can be fairly labour-intensive, this laser marking technology offers increased efficiency, accuracy, and automation. The laser works by using high-powered beams to burn or etch a design or code directly onto the surface of the material.

One of the most remarkable features of the YJ Link NOVLUX Laser Marker is its in-built flipper for double-sided etching. This allows Active-PCB to mark both sides of a printed circuit board in a single, efficient cycle.

The integrated extraction system further enhances the process, ensuring that fumes and particles generated during marking are efficiently removed, contributing to a cleaner and safer working environment.

Why is This Important for Active-PCB?

The implementation of the YJ Link NOVLUX Laser Marker will replace our current barcoding process and will allow us to streamline our operations, making processes faster, more reliable, and less prone to human error.

1. Enhanced Traceability

One of the most significant advantages of laser marking is enhanced traceability. With this technology, we can now etch unique identifiers like barcodes or logos directly onto PCBs, making it easier to track each product at every stage of production and through the supply chain. This ensures we can maintain accurate records and quickly trace any issues right back to the source.

2. Improved Repeatability

Laser marking offers incredible precision and consistency, meaning that the same design can be replicated with perfect accuracy, no matter how many times the marking is performed. This improved repeatability ensures our products maintain high standards of quality, reducing defects and enhancing our overall manufacturing process.

3. Barcode Data Matrix Capabilities

One of the standout features of this new system is its ability to apply 2D data matrix barcodes down to as small as 5x5mm (see below) – with potential to go as small as 3 x 3mm.

Despite its tiny size, it doesn’t compromise readability or functionality, enabling us to mark more compact and complex products with precise codes.

The ability to incorporate a 2D barcode means we can store and encode more information in a smaller space compared to traditional 1D barcodes.

Upcoming Training with Altus for Staff Using The YJ Link NOVLUX Laser Marker

Next week, our team will undergo training provided by Altus, the specialists behind the YJ Link NOVLUX Laser Marker. This training will ensure that we fully understand how to use the system, optimise its capabilities, and get the most out of this investment. The team at Altus has been incredible in supporting us throughout this process, and we’re excited to dive into the specifics of the machine’s operation.

Watch the laser marker in Action

We’ve already captured some footage of the new machine in action! In the clip, you can see the YJ Link NOVLUX Laser Marker etching the Active-PCB logo onto a PCB.

You can learn more about the YJ Link NOVLUX Laser Marker through this link on the Altus website and explore how PCB and final assembly traceability through marking is becoming the future of manufacturing.

Stay tuned for more updates as we continue to innovate and improve our processes!